This signal is used to calculate engine rpm and crank angle position for injector firing and ignition triggering from the ECU. The sequential system also requires a “Crank” signal, generated at a specific crankshaft angle on each cylinder. This signal is typically generated once every two crankshaft revolutions on a 4 cycle engine and is most commonly referred to as the ” CAM” or “SYNC” signal. Triggering a sequential system is more complicated than a group fired system, as it requires a separate triggering signal to reference the start of the injector firing sequence. Some systems can even be programmed for different injection phasing for each speed site in the fuel map. This improves idle quality, low speed engine smoothness, and fuel economy. This system triggers each injector at a precise crank angle on every cylinder, usually near top dead center overlap (intake valve opening). Be sure your fuel pump is capable of supplying the engine with the volume required at a higher fuel pressure. Be careful about running the fuel pressure too high, as some ECUs don’t have enough current to lift the disc or pintle in the injector consistently off the seat against this added pressure, which will result in poor fuel distribution. We also like the better atomization achieved with the higher pressure and it sometimes gives better power and economy. The amplitude of the pressure spikes will remain about the same, but will be relatively smaller based on the percent change in injector flow. We often run about 72 psi instead of the more normal 36 to 43. Running higher overall system pressure also helps. A large diameter smoothes out the pulses quite well when compared to smaller sizes. Kinsler extruded aluminum fuel rails are.

It often helps to run a larger diameter fuel rail. The simultaneous pluses can reinforce each other at some rpm to give unusually high pressure pulses, sometimes causing poor fuel distribution. In a group fired system you often trigger two or more injectors at a time in a given fuel rail.

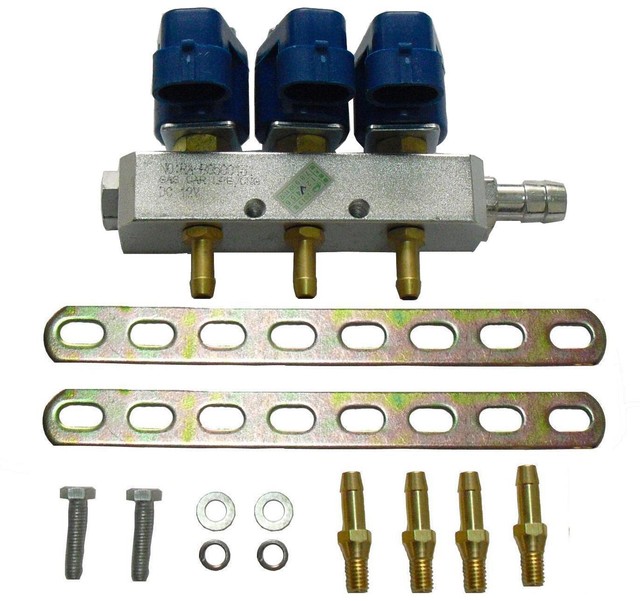

Open throttle where the flows are the highest. Since EFI injectors turn on and off, the interrupted flow causes pressure waves to bounce around in the fuel rails, especially at wide This can cause erratic mixture conditions to exist in that cylinder, especially during low speed engine operation, due to the small amount of air movement in the intake runner. When the intake valve opens, only a portion of the fuel injected will be in suspension when the air enters the cylinder, the remainder may be running down the port wall as liquid. If an injector is triggered at the wrong crank angle, fuel may collect in areas of the intake port or cling to the runner walls. The problem is that while some injectors will be close to properly timed, others will not. The good thing about the group fired system is it’s low cost. The ignition system or crank trigger provides the signal to the electronic control unit (ECU) for speed input and thus This injection system generally triggers a group of the injectors simultaneously. Below is some of the basic information on the two types of systems so you will have a better understanding of their operation. There are two basic types of multi-port EFI : Group and Sequential. The first decision on EFI is which type of electronic control unit is the best suited for the application and budget. Our staff is here to help you sort through the ‘mysteries’ and give you the “real” information so that you can make an informed and educated decision. Kinsler offers six manufacturers electronics, each manufacturer has several models. When choosing an electronic fuel injection system there are many features and options, it can be confusing. The most commonly sensed inputs are:ģ) Barometric pressure or manifold absolute pressure (M.A.P.)ĥ) Water and/or oil temperature, and sometimes fuel temperature With it’s many sensors and input signals it can be tuned to meet the demands of an engine operating over an extremely broad range of conditions.

Electronic fuel injection metering, when properly designed and programmed, is today’s accurate way to introduce fuel to an internal combustion engine.

0 kommentar(er)

0 kommentar(er)